Teflon sleeves

Polytetrafluoroethylene or PTFE, better known as Teflon, was discovered by 27-year-old chemical scientist Roy Plunkett in 1938, who accidentally discovered that tetrafluoroethylene gas he had pumped into a pressurized cylinder spontaneously polymerized into a white paraffin-like powder. In 1941, the company in which Plunkett worked was granted a patent for Teflon, and in 1949 the company became a division of the American company DuPont. From the day of its appearance to this day, the material finds its wide application and is used in many industries. Teflon gained the greatest fame due to its widespread use in the production of non-stick dishes. Teflon is used in the chemical, electrical and food industries, in medicine, on vehicles, for military purposes.

Fluoroplastic hoses

PTFE hoses are also made of Teflon. Fluoroplastic hoses (PTFE - hoses) or Teflon hoses are primarily intended for flexible connection of hydraulic lines in various machine mechanisms where increased resistance to high temperatures, pressure and aggressive environments (for example, in paints), as well as working in conditions of increased vibration, pressure and hydraulic shocks of the working fluid.

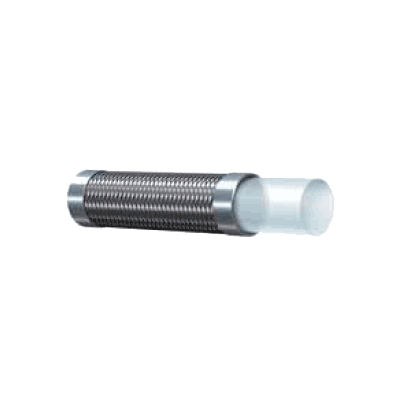

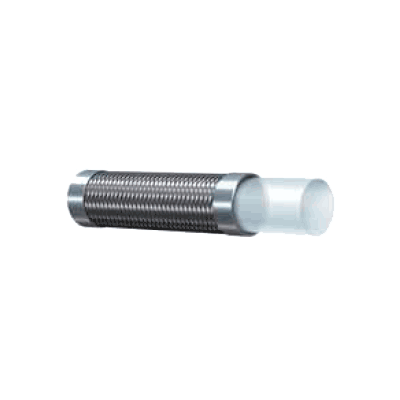

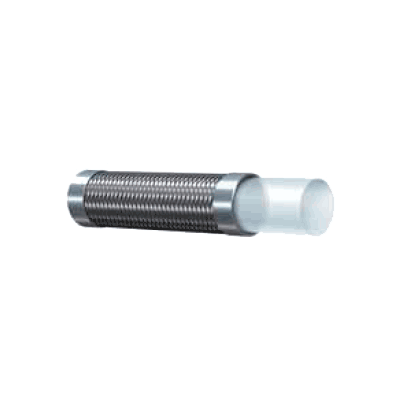

Teflon hoses: design

Flexible Teflon hoses have a simple design:

- The inner layer is a fluoroplastic tube;

- Outer layer - stainless steel braid, which increases the strength characteristics of the hose and protects against mechanical damage.

Fluoroplastic tube is of two types - smooth and corrugated. A corrugated tube increases the flexibility of the sleeve, but the sleeve costs significantly more, withstanding less pressure, unlike smooth-walled sleeves. Therefore, in special cases, they require strengthening (booking) with an additional metal spiral. To remove static electricity, the tube can be made with the addition of special anti-static carbon additives. Most often, PTFE sleeves are connected using conventional hydraulic fittings crimped with smooth couplings.

PTFE sleeves: benefits

The main advantages and properties of PTFE hoses are:

- Teflon is resistant to many liquids and gases, including alkalis, solvents, oils, aggressive acids;

- Teflon sleeves operate over a wide range of temperatures, indicating that PTFE sleeves have a wide range of heat resistance;

- PTFE hoses are flexible and lightweight (more flexible and lighter than pressure hoses and metal hoses);

- Thanks to the Teflon tube, the sleeve has a low coefficient of friction, which ensures a small pressure drop;

- PTFE hoses are easy to clean, which increases their service life, the transported substance does not stick to the wall of the photoplastic hose;

- Teflon hoses are resistant to precipitation, ultraviolet rays.

- 1SS

- 1SS corrugated

- 2SS

- IP

- IM

- IG

- IC corrugated

Buy Teflon Hoses

In our company you can find out the price of fluoroplastic and teflon hoses of various types and sizes. We offer Teflon hoses (PTFE - hoses) with one and two braids, with a smooth and corrugated inner tube. You can buy these products not only in St. Petersburg, but also in other cities of Russia in which our branches are opened: Moscow, Krasnodar, Chelyabinsk, Kemerovo. You can also find out the price and buy a braided fluoroplastic sleeve from our dealers or contact the network of our workshops H-POINT.