Crimping couplings for VFD crimping of Interlock series

The process of making a hose with Interlock fittings is quite different from crimping hoses with universal fittings and couplings.

Interlock fittings and couplings are crimped onto the hose using specialized VFD crimping equipment. This procedure should be performed by qualified specialists, on tested and certified equipment. Even more important is the use of tested and, most importantly, compliant Interlock crimp couplings and fittings.

The manufacturing process of a high and impulse load hose consists of 4 main steps.

- First of all, measure the desired sleeve length and cut the sleeve.

- Use debarking equipment to remove the inner and outer layers of the sleeve rubber. Do not forget – this is a mandatory procedure when using Interlock fittings.

- After removing the rubber layers, mount the fitting and coupling on the hose. This can be done either with a rubber mallet or with a special pneumatic pusher. Afterwards, the fitting is pressed with a pressing machine according to the INTERLOCK fitting pressing tables.

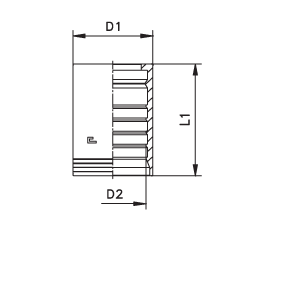

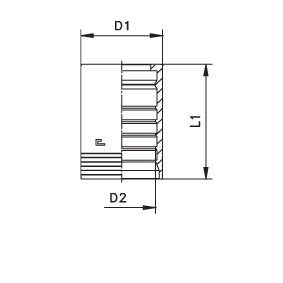

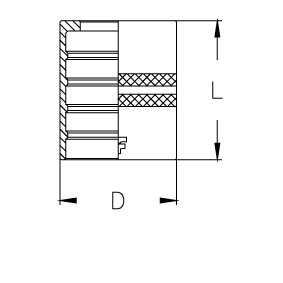

The design of INTERLOCK fittings

The design of the INTERLOCK series differs from the universal series. The inner surface of the Interlock hose coupling is made in the form of a herringbone and has a double lock. This design allows for a reliable, strong connection that will withstand high loads. Due to the metal-to-metal interface, Interlock products can be used under high loads.