Interlock fittings

When high and very high pressures are used to operate machinery in a hydraulic system, standard fittings cannot be used when pressurizing RVD . With standard fittings it is impossible to make a strong connection that will work under high loads.

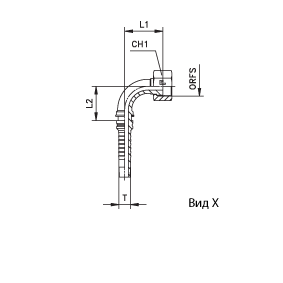

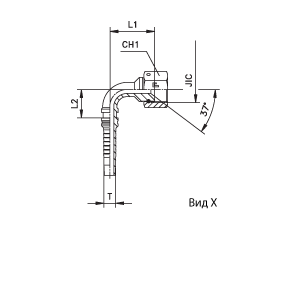

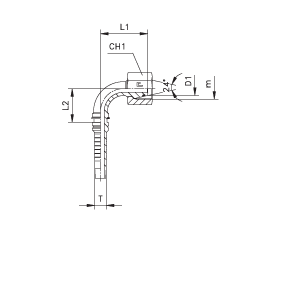

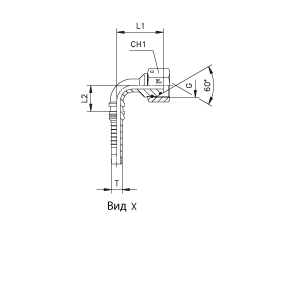

To ensure a reliable and high quality connection, our company offers a special product - Interlock fittings. Interlock fittings differ from standard fittings and couplings in their design, the pressing technology also has its own differences.

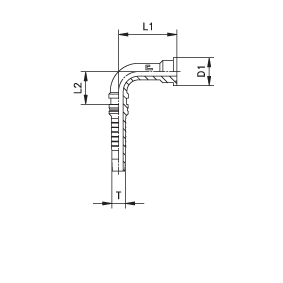

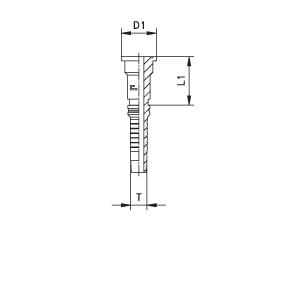

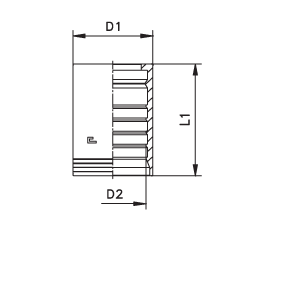

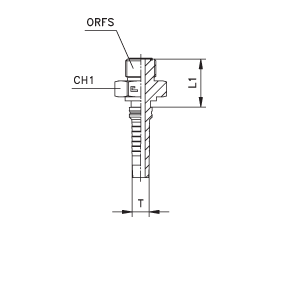

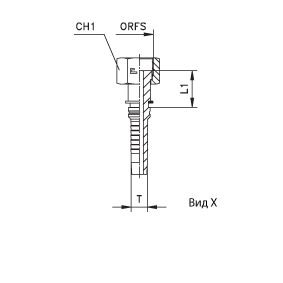

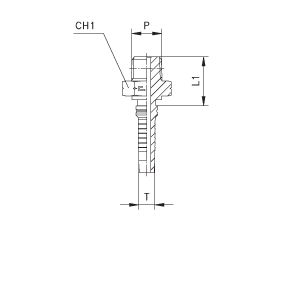

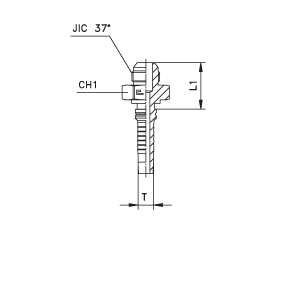

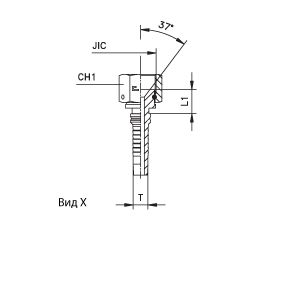

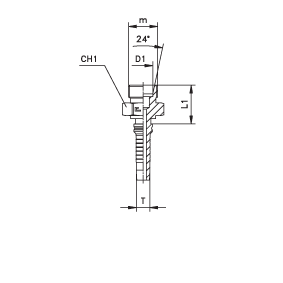

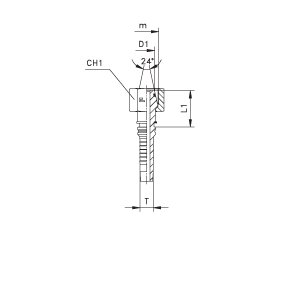

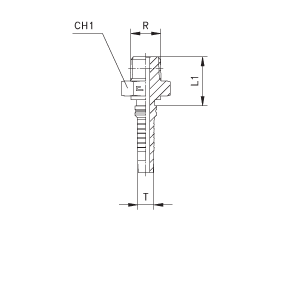

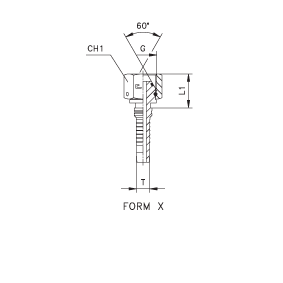

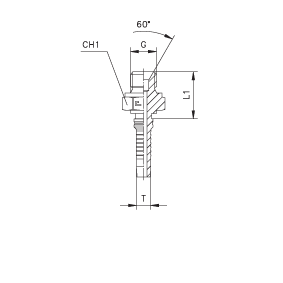

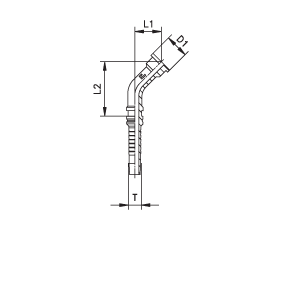

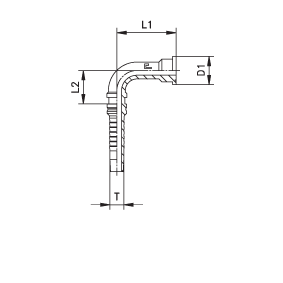

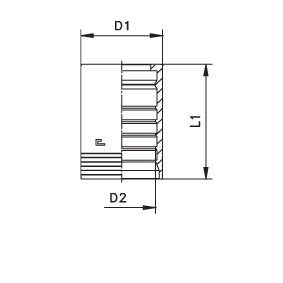

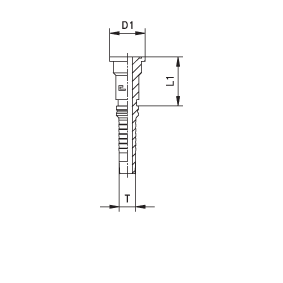

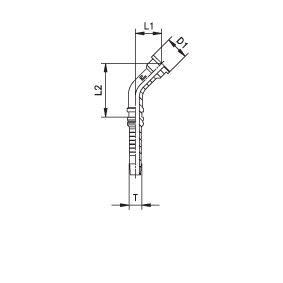

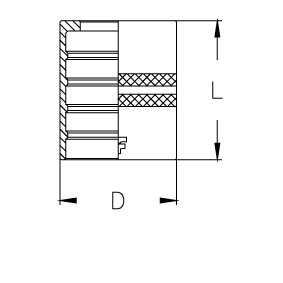

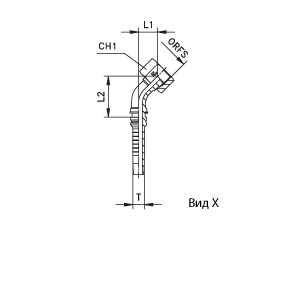

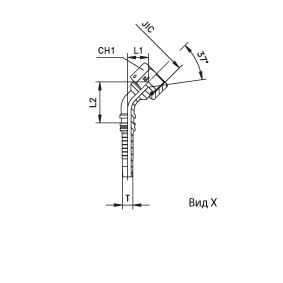

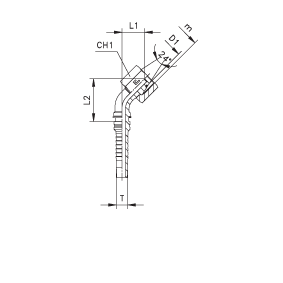

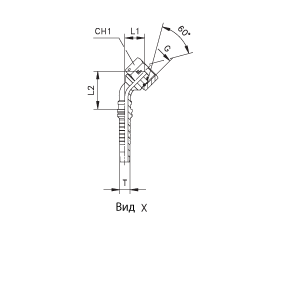

The design of fittings and couplings Interlock

The main difference between the pressing process of braided and coiled hoses is the removal of the rubber layers on coiled hoses. This procedure is necessary to increase the adhesion of the fitting and coupling to the outer and inner layers of the hose. The teeth of the coupling and fitting fit snugly against the winding of the hose, ensuring a strong connection.

The main difference in the design of the Interlock coupling is the shape of the teeth. In the Interlock coupling it is made in the form of a herringbone, this design is more reliable when working with high pressure. The shape of the fitting is also different from the standard, it is also herringbone shaped.

We offer Interlock fittings in various types and sizes. We offer Italian Interlock fittings and couplings from the manufacturer. All products presented in the Standard class are manufactured in Italy. Standard class products – this is an optimal price-quality ratio.